Garage Floor Epoxy Alternative

Epoxy garage floors have been around for a long time — so long that people often use “epoxy” as a generic term to mean “floor coating.” But garage floor epoxy is a specific material that has some serious drawbacks. That’s why, after a lot of research, we chose polyaspartic for our concrete floor coating product.

The Truth About Epoxy Floor Coatings

Epoxy concrete floor coating takes nearly a week to cure and because it’s so inflexible, it cracks easily, allowing moisture to seep beneath it, breaking the bond with the concrete below. This makes it a less durable option down the road. Throughout our exhaustive research, we found that epoxy flooring has multiple serious drawbacks, including:

Why a Polyaspartic Floor Coating Is Better Than an Epoxy Floor Coating

When it comes to a floor coating, you should choose the kind that lasts the longest. And polyaspartic beats epoxy in that area without question. Why? Just take a look:

Hello Garage 100% Polyaspartic vs. Other Floor Coating Options

| Epoxy | Polyurea | Polyaspartic | |

|---|---|---|---|

| Bonds strongly to concrete to avoid peeling and flaking over time | X | ||

| UV resistant, so it won’t yellow or break down over time | X | X | |

| Greater flexibility to prevent cracking | X | ||

| Appropriate hardness for optimum impact, abrasion and crack resistance | X | ||

| Resistant to hot tire pickup | X | X | |

| Resistance to chemical damage | |||

| Looks great for years to come | X | X |

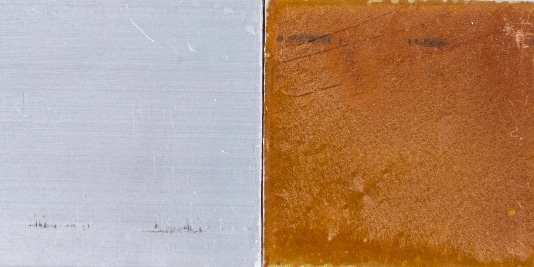

Epoxy Coatings and UV Exposure

The sunlight that warms our bodies and nourishes our plants also contains ultraviolet radiation or UV for short. In fact, it’s overexposure to UV radiation that causes sunburns. And just as it can harm your skin over time, UV radiation can cause certain floor coatings to yellow and fade, including epoxy floor coatings.

Polyaspartic: The UV-resistant concrete floor coating.

You might not think your garage gets much exposure to the sun, but if you leave the garage door open while you mow the lawn, for instance, that exposure year after year can cause your epoxy garage floor to yellow and fade. And if you’re coating an exterior space, forget it; epoxy is not the way to go. Only polyaspartic concrete flooring will give you the UV resistance you’re looking for.

Polyaspartic

Epoxy

Clear Coat

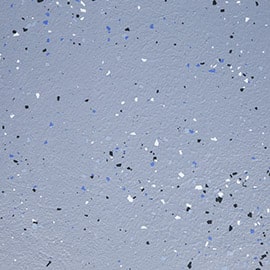

Clear Coat on HG Pearl Flake

Polyaspartic — The Superior, More Affordable Concrete Floor Coating

The beauty and durability of polyaspartic simply make it a better solution for improving your garage, patio, basement or other interior or exterior concrete surface. And though a high-quality, 100% polyaspartic concrete coating typically costs a bit more than an epoxy floor coating initially, over time, it’s a better value because it typically lasts up to four or five times longer when professionally installed.