The Best Alternative to Epoxy Garage Floors

Epoxy garage flooring has been an industry staple for decades, becoming so widespread that the word “epoxy” is practically synonymous with floor coating. However, epoxy flooring’s initial visual appeal and protection will wane under the stress of temperature fluctuations, heavy traffic and prolonged UV exposure.

At Hello Garage, we confidently recommend polyaspartic flooring as the best floor coating option. This seamless, high-performance floor coating option offers superior durability, performance and resistance to wear and tear. Unlike epoxy floors, polyaspartic coatings maintain their color and integrity for years, withstand the rigors of daily use and cure within 24 hours — minimizing installation downtime.

The Truth About Epoxy Garage Flooring

Epoxy floors for garages have several significant drawbacks that make them less than ideal. One issue is the extended curing time — epoxy can take nearly a week to fully cure. Additionally, this inflexible garage flooring material cracks easily, allowing moisture to penetrate the surface and break the bond with the concrete below. This vulnerability compromises the floor coating’s integrity, creating ongoing maintenance headaches.

If you’re searching for the best coatings for garage floors, polyaspartic is an epoxy alternative that cures faster and provides outstanding protection. Through our exhaustive research, we discovered polyaspartic flooring is excellent at weathering the demands of everyday garage use, providing a longer lasting and more reliable garage flooring solution without disadvantages like these:

Why Polyaspartic Floor Coatings Are Better Than Garage Floor Epoxy Coatings

Our team installs polyaspartic floor coatings as an alternative to epoxy garage floors. Ultimately, our decision to move beyond traditional epoxy flooring reflects our commitment to providing high-quality, reliable garage flooring that delivers exceptional value and performance.

Here are a few reasons to upgrade your garage floor and invest in your peace of mind with a polyaspartic floor coating.

Hello Garage 100% Polyaspartic vs. Other Floor Coating Options

| Epoxy | Polyurea | Polyaspartic | |

|---|---|---|---|

| Bonds strongly to concrete to avoid peeling and flaking over time | X | ||

| UV resistant, so it won’t yellow or break down over time | X | X | |

| Greater flexibility to prevent cracking | X | ||

| Appropriate hardness for optimum impact, abrasion and crack resistance | X | ||

| Resistant to hot tire pickup | X | X | |

| Resistance to chemical damage | |||

| Looks great for years to come | X | X |

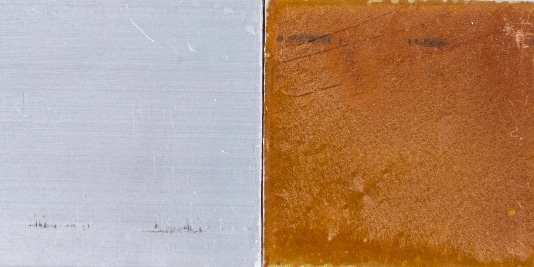

Epoxy Floor Coatings and UV Exposure

The sunlight that warms our bodies and nourishes our plants also contains ultraviolet radiation. If you’ve ever gotten a sunburn, overexposure to UV radiation was to blame. And just as it can harm your skin over time, UV exposure can make your epoxy garage floor coating discolored and faded.

Polyaspartic: The UV-Resistant Concrete Floor Coating

You might not think your garage gets much sunlight. However, if you’re one of the many people who leaves your garage door open while you do yard work, that exposure will add up over time, making your garage floor epoxy coating look dingy and worn-out. And if you’re coating an exterior space, forget it; epoxy is not the way to go. Only polyaspartic concrete flooring will give you the UV resistance you’re looking for.

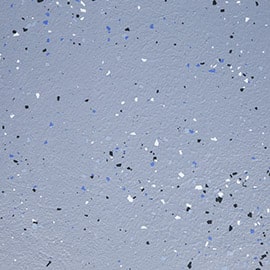

Polyaspartic

Epoxy

Clear Coat

Clear Coat on HG Pearl Flake

Polyaspartic — The Superior, More Affordable Concrete Floor Coating

Polyaspartic floor coatings’ beauty and durability are ideal for improving your garage, patio, basement, or other interior or exterior concrete surface. And though a high-quality, 100% polyaspartic concrete coating costs a bit more up front, this epoxy alternative is a better value over time because it typically lasts up to four or five times longer when professionally installed.